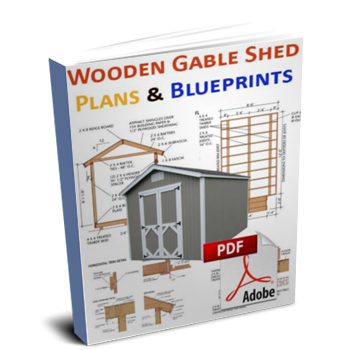

Here are some detailed and complete shed crafting plans and blueprints for building that shed you always wanted.

It doesn’t matter if you want a shed with a gable, gambrel or lean-to roof. We have shed blueprints for them all. Take a look at out collection of plans below.

Lean To Shed Assembly Plans For Lovely Slant-Roof Garden Sheds

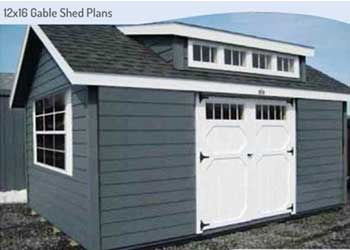

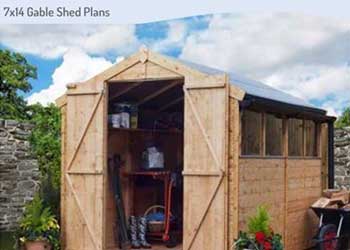

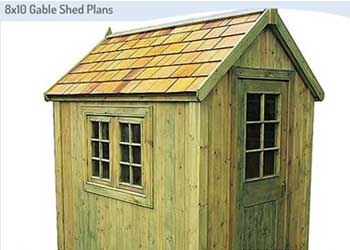

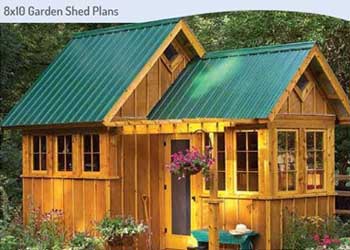

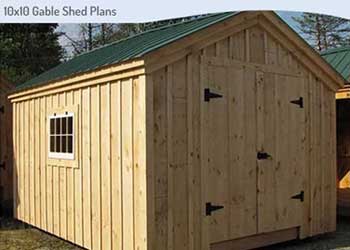

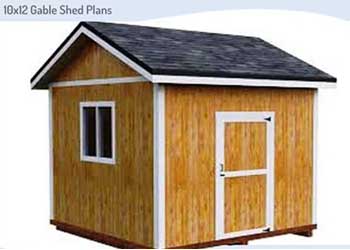

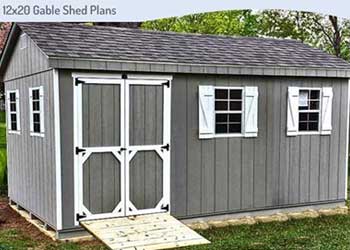

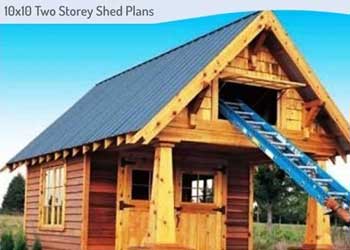

Storage Shed Design Blueprints For Gable Roof Sheds

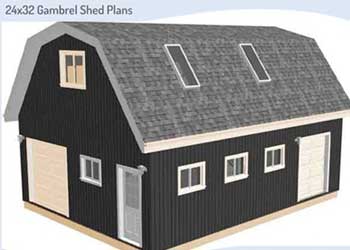

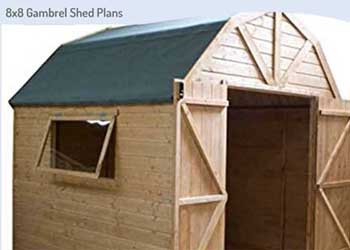

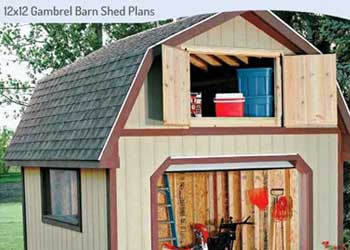

Gambrel Shed Framing Plans For Barn-Style Outbuildings

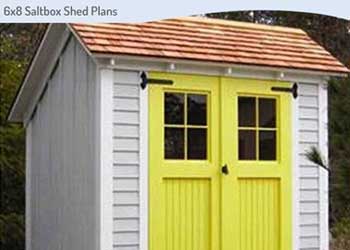

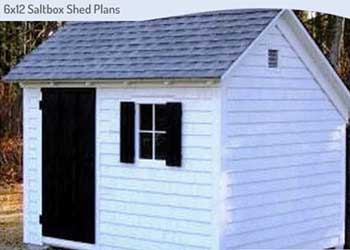

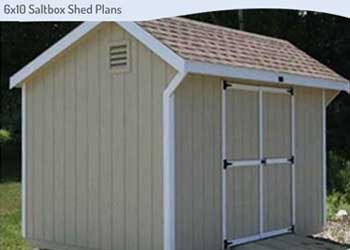

Saltbox Shed Design Plans For Durable Wooden Sheds

Utility Shed Crafting Plans For Practical Backyard Sheds

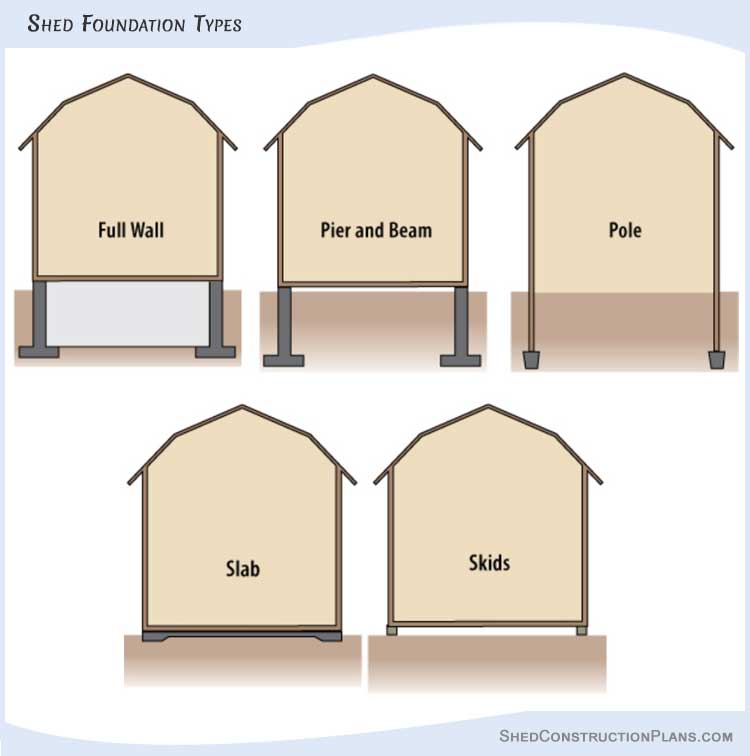

Types of Shed Foundations

A wall foundation is constructed by stacking a continuous series of concrete blocks or pressure-treated wooden bricks along the perimeter of the shed. This is useful in areas where the weather is too cold to pour concrete.

A pier and beam base is an elevated foundation consisting of interconnected beams resting on piers. As the base is elevated, it prevents flooding and is easier to repair.

Pole foundations are commonly used for crafting huge barns. It is built by driving wide circular poles into concrete footings located deep inside the ground below the frost line.

A concrete slab foundation consists of a six-inch layer of a poured concrete mixture. The mixture is poured over a layer of compacted and leveled gravel.

Skid foundation is created using pressure-treated 6×6 timber skids that rest on ditches filled with compacted gravel.

The first stage when planning to construct any outbuilding is to consider how you will use it. Keep in mind how your use for the shed may change in the future and allocate enough space to grow.

Before you finalize any shed crafting plans, you must check with the local building councils and find out all the applicable regulations and codes. Most areas will need a permit for constructing any shed larger than a certain size. They may also have rules on what kind of foundations need to be used. It is best to consult an official from the building council and understand all necessary requirements before you choose a blueprint.

Creating a shed can take a lot of work and a good amount of money. So it is ideal if you build a shed that is slightly bigger than your current requirement. Making any modifications to the shed will always be more expensive than doing these changes today as part of the construction process.

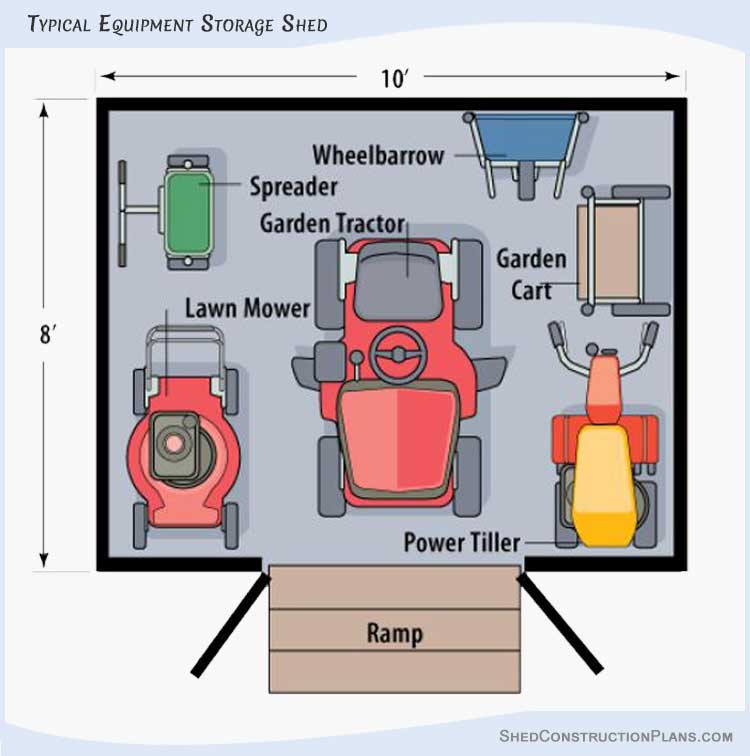

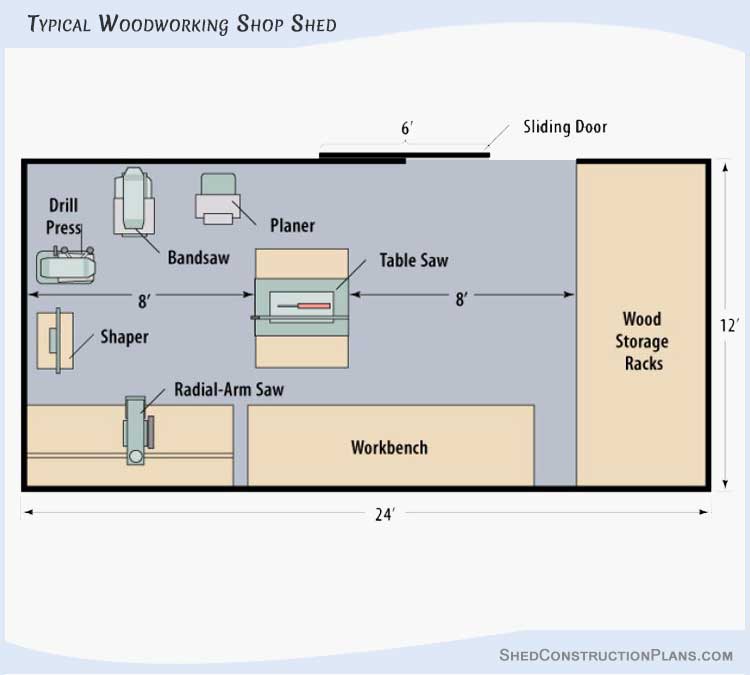

You need to keep a minimum of one-foot space around any large pieces of equipment that will be stored in the shed. Measure the equipment dimensions and increase them accordingly when considering the size of the shed you will need.

Recommended Shed Sizes

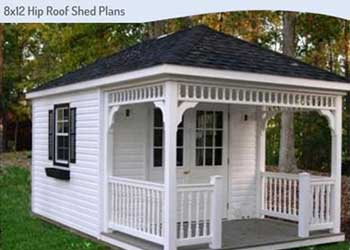

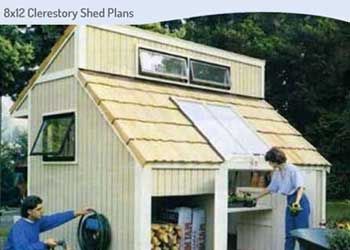

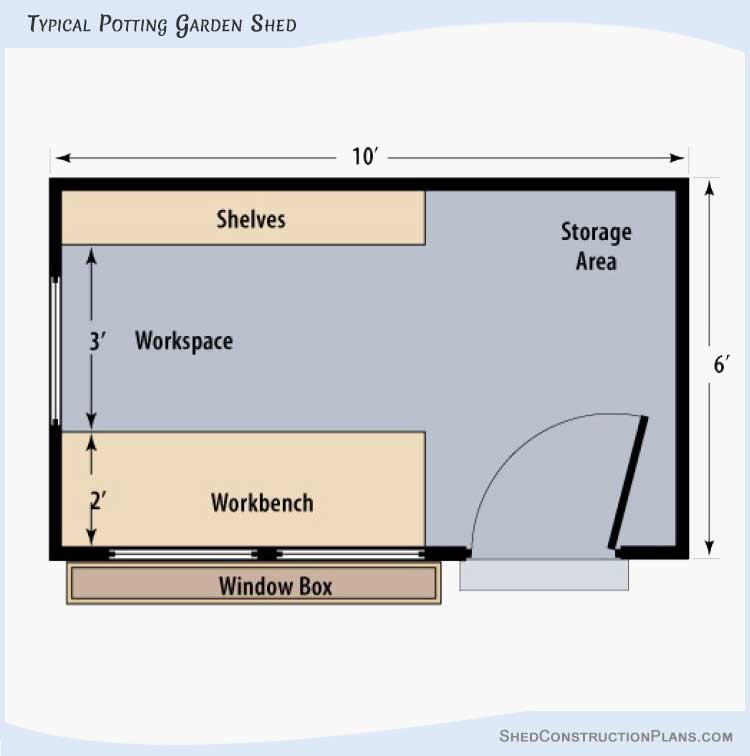

A compact potting shed with a workbench and shelves is ideally 6 feet by 10 feet in size. If you plan on doing some serious gardening down the line and want to keep room for growth, then it may be better to go with an 8×12 building.

Equipment sheds are usually at least 8 feet by 10 feet. Of course, this will vary based on how much equipment you plan on storing inside. Make sure to build large double doors and a ramp to make it easy to move your gear in and out of the building.

If you would like to set up a woodworking shop inside your shed, then a space of 12 feet by 24 feet is recommended. This will allow sufficient space to store your workbench, table saws, and storage racks and still leave enough room for you to freely move around.

Based on the usage of your shed, you may also need to run electricity and plumbing to your shed. Even if you are building just a storage shed, you should install at least one light inside the shed and one right outside the door. This will make it simpler to use the shed during the night.

Depending on what materials will be stored inside the shed, you may also need to install exhaust fans or heating systems inside the building. It is also recommended to install an electrical outlet inside the shed where you can plug in a vacuum cleaner or use it as a charging station for your power tools.

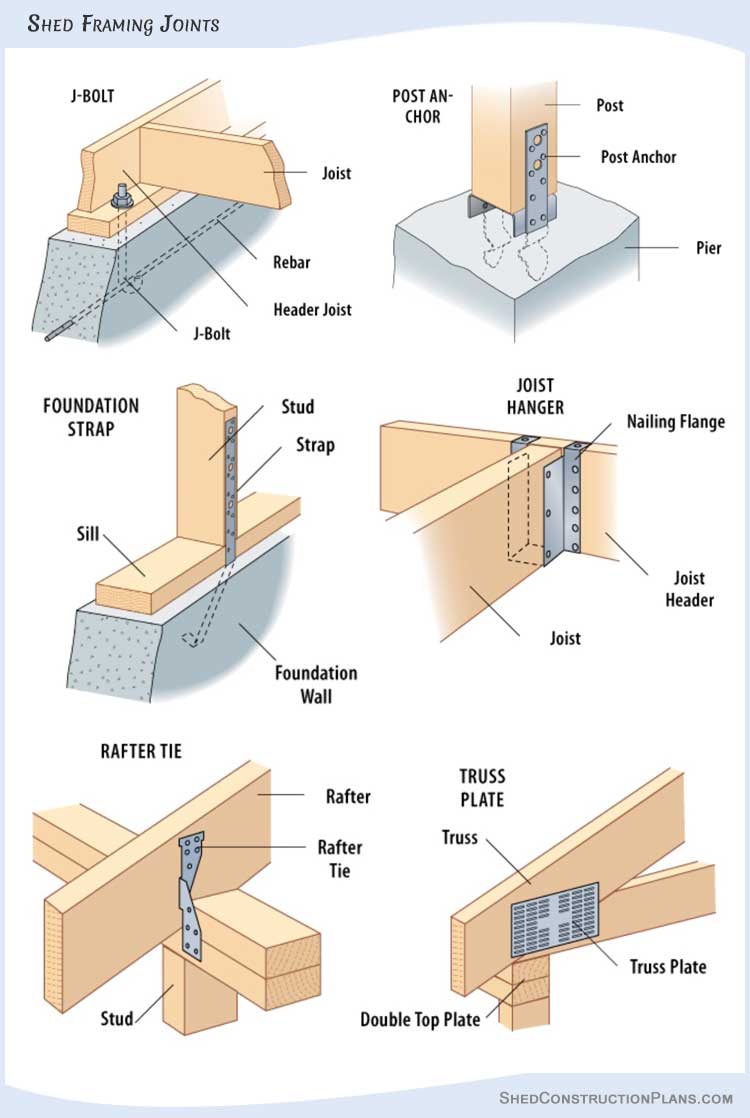

Common Shed Framing Joints

You will need many different kinds of joints to frame different sections of the shed. Building regulations sometimes require the use of metal anchors or ties to reinforce these joints. This is especially true in areas that are prone to hurricanes and earthquakes.

Metal ties are commonly used to connect joist hangers to the floor and header joists and also to connect rafters to the top plate. Metal fasteners are sometimes used to secure concrete piers to posts and fasten neighboring sheathing panels.

Common Shed Layouts

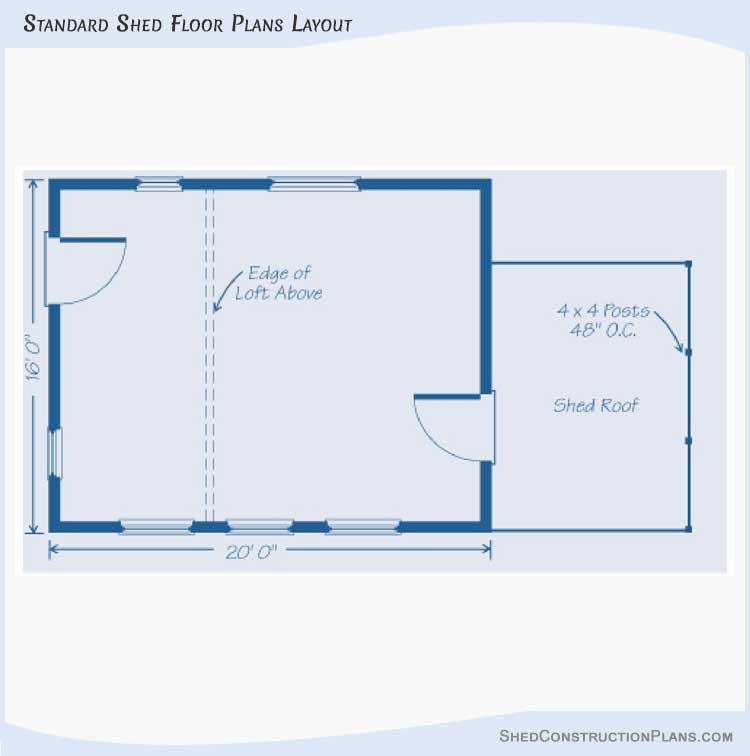

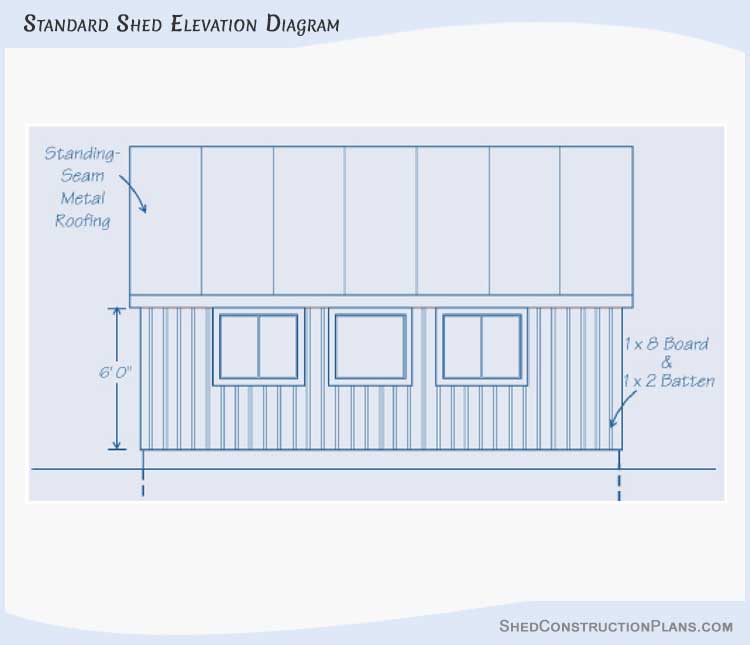

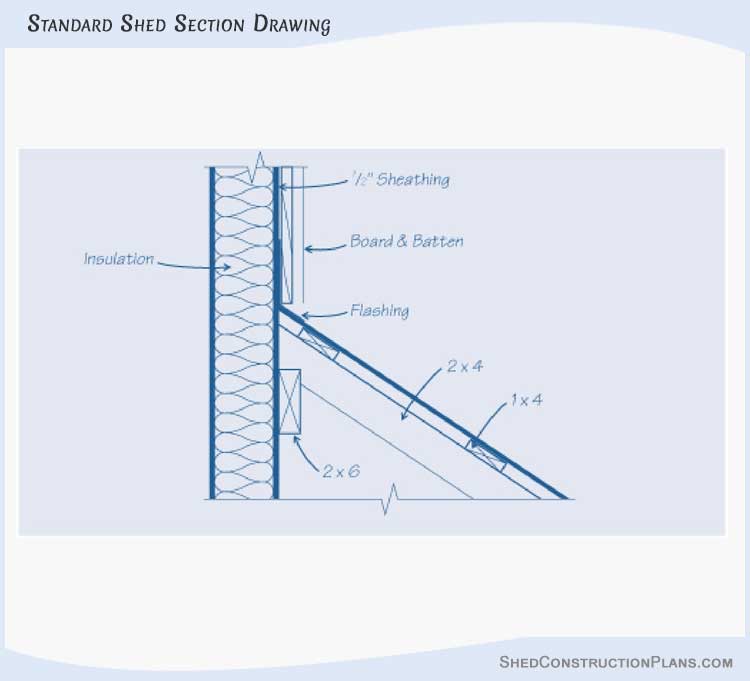

Shed building plans typically consist of floor plans, elevation diagrams, and section details.

Shed Floor Plans

The floor plans for a shed will illustrate the positions and dimensions of the inner and outer walls. It will also show the placement of the doors and windows along with additional features like a porch or staircase.

Elevation Diagrams

A one-dimensional snapshot of any one face of the shed is known as an elevation diagram. If two sides of the shed are alike, only 2-3 elevation diagrams are sufficient. If all four sides of the shed are different, the blueprints will show the front, back, left, and right elevation drawings.

Section Details

A cutaway drawing of a foundation, wall, or roof that displays the inner details of the structure is called a section diagram. These section details illustrate how the inner components of a structure are framed and connected to other members of the shed.